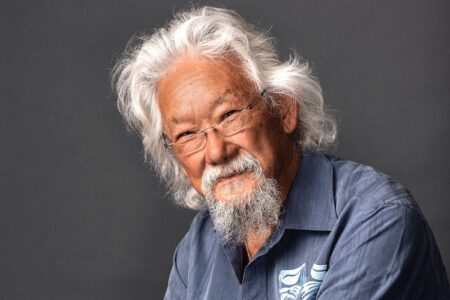

BUSINESS FEATURE: Eagle rises from the ashes of Canpar

Five years ago Greg Harasemow thought his life was secure in his long-term job at Canpar Industries planning for efficiencies in the production line. Today, Harasemow’s company Eagle Mountain Custom Metalworks Ltd. is growing with hopes of hiring staff as the company expands in the future. The custom metal work offered by Eagle Mountain is just that: custom. Harasemow works with customers to create their projects. Eagle Mountain creates light industrial metal work to metal art and everything in between. Operating in Grand Forks, but serving the globe, Eagle Mountain was recently recognized as ‘Small Business of the Year” from Community Futures Boundary.

After 23 years at Canpar, where Harasemow he started when he was 25-years-old in the early 1980’s, he never thought he would be hanging out his own shingle. Greg started at Canpar as a welder and worked his way up to Maintenance Planner /Project manager. Eagle Mountain opened in the spring of 2008 after Harasemow completed the Community Futures Boundary’s self employment program. Although the company is solely owned by Greg, his brother Len is heavily involved with the operation of the business.

“Now that I look at it, there was nothing anybody could have done in the economy,” said Harasemow about the demise of Canpar. “We were one of the first casualties of the whole economic crash. All of a sudden they said, guess what, we don’t have work for you anymore. We (Greg and his brother Len who also worked for the company) had options, it’s not like either one of didn’t have options. But the jobs were up north and I didn’t want to move.”

Greg and Len initially thought that perhaps they could expand on their music studio in town and make a go of that as a business. But as they got into the market research, they realized that the potential was extremely limited. Somebody they knew tweaked them to explore the market for their metal art that they created for fun – metal picture frames, wine racks, decorative lit metalwork, etc.

So Greg explored the art side of metal work as his potential new business. Harasemow said he felt very comfortable with the business model because of his background in the industry – he was connected with suppliers and had established great relationships with them. But he soon saw the flaws in the art industry. Often a piece of art can sit in a gallery for months before it sells, he explained. Without an ongoing consistent cash flow for his business, Greg realized that it could be very difficult to earn a living. So he decided to explore other possible metal work.

“My background at Canpar really set me up to do this,” explained Harasemow. “We walked over to Y & R Water and enquired about making sprinklers. So we got the sprinkler contract. Then, before you know it, we were starting to do little railing jobs because no one was doing them in town.”

Then Greg and Len started to translate their art into light industrial applications. “We don’t just do railings, we do artistic railings. We started adding multi-media stuff,” he continued.

As it got known that Eagle Mountain was doing some different applications, they were soon getting calls for construction contracting. Greg said they are unique in providing light commercial work, unlike the larger metal work companies in Grand Forks like Unifab Inc. and WD Sheet Metal Ltd. Their customers range from private home owners to construction companies with some international customers coming from website enquiries.

They have done work for the construction of the new Boundary Hospital wings, repairs on the Grand Forks Aquatic Centre, and new home building. They have expanded their lines to include: railings, fencing, powder-coated railings and glass railings.

“Little by little we’re increasing our product lines. Unfortunately, we’re getting away from the art a little bit,” laughed Harasemow. “I’d love to have more time to do the wine racks and art projects, but right now (to do that) you’ve got to travel which takes a lot of time. There’s a whole untapped potential of services we can fill.”

Harasemow loves the creativity of the business he’s developed. If people have ideas, he welcomes them to come to him and help design their needs. “Rarely does somebody come to us and say ‘can you do this,’ and we say ‘no that’s out of our scope.’ This is what custom metal work is all about: we work with the people. I love making things. What we’re geared towards is to ensure the customer has ownership in the design.”

Part of their increasing product line includes owning and operating a mini-storage facility on Donaldson where the shop is also located. Just over a year into the business, Harasemow is happy that the company is more established now, people are getting to know their work, and they are able to offer more and more services. His greatest lesson is learning to adapt to what customers want while maintaining his high standards for quality.

Harasemow said he couldn’t have come this far without the support of his family and friends. “It’s a long hard road, and hopefully the time we’re putting into it will pay off in the end,” he said. “We’re here to establish a business and have something going consistently in the Boundary area for many years.”

A portfolio of Eagle Mountain’s product lines and art is available in their office and online at www.EagleMountainCustomMetalWorks.com. Some of their work can be seen at Grand Forks Aquatic Center, the railings on the Black Train Bridge, wine racks at the local Liquor Store and at the Granby River Dental Clinic sign among many others.